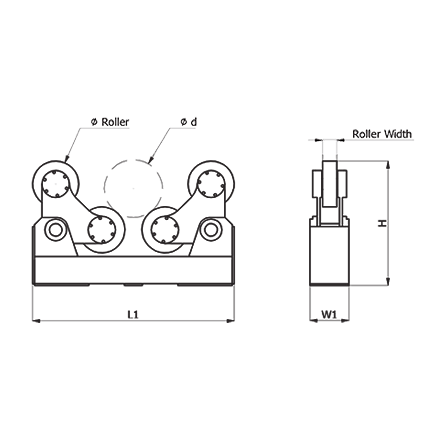

Self Align Rotators

B-SAR

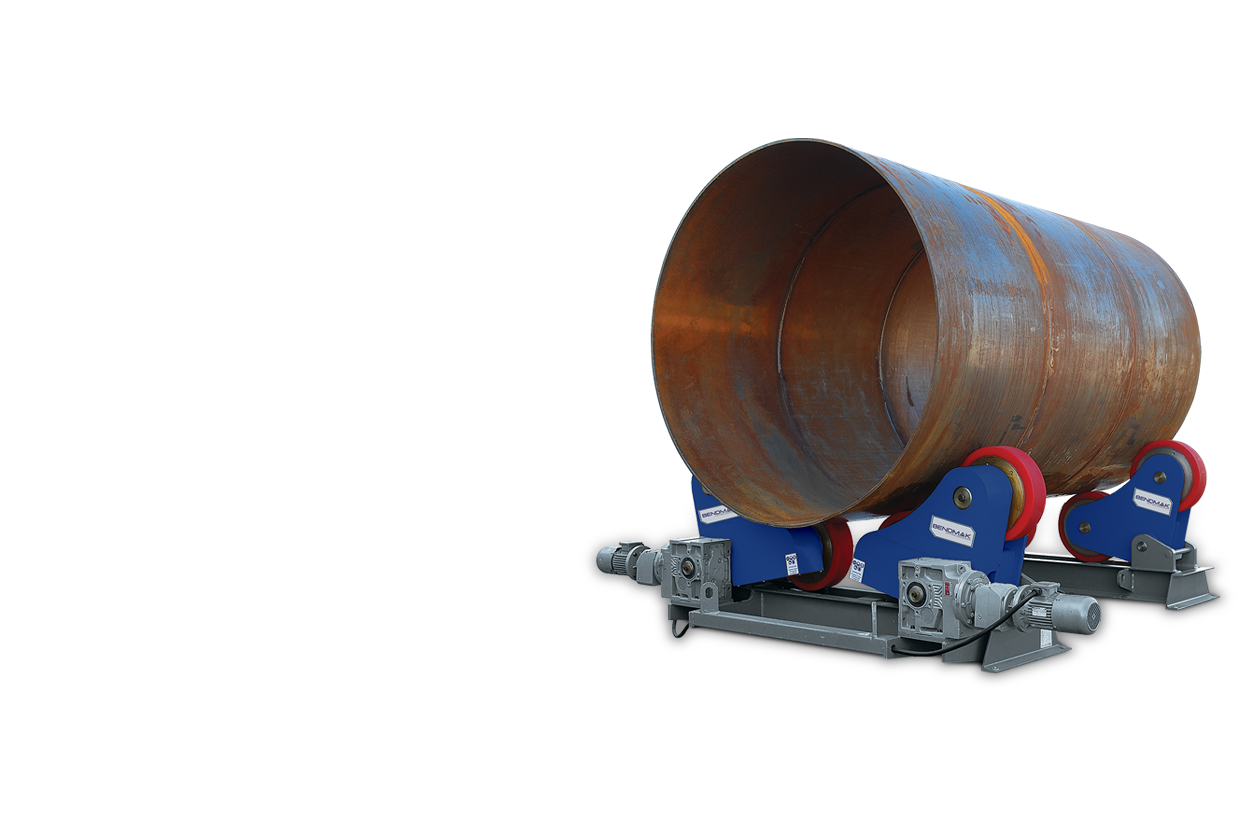

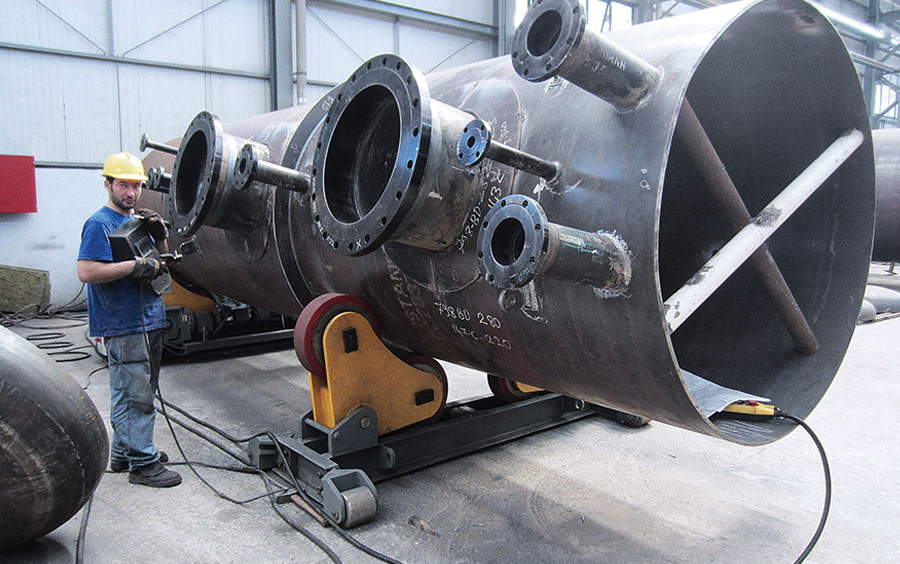

Self-aligning rotators are an ideal solution for conditions where diameter of the rotated work pieces is variable. Used for rotating circular parts such as tanks, pressurized containers, tower piping, boiler, silos, reactors, fuel drums etc. These rotators are able to adjust wide diameter ranges automatically. No additional time or effort is required to commence rotation of the work piece.

Rotators improve the speed and efficiency both during automatic and manual welding and have an important role in steel construction workshops by minimizing crane operation.

Operators can rotate the pieces mounted on the rotator clockwise or counterclockwise, precisely, well-aligned and controllable via control panel, in easily adjustable speeds. Self aligning rotators comprise of two units as 1 drive and 1 idler unit. Number of drive and idle units can be changed according to the application conditions.

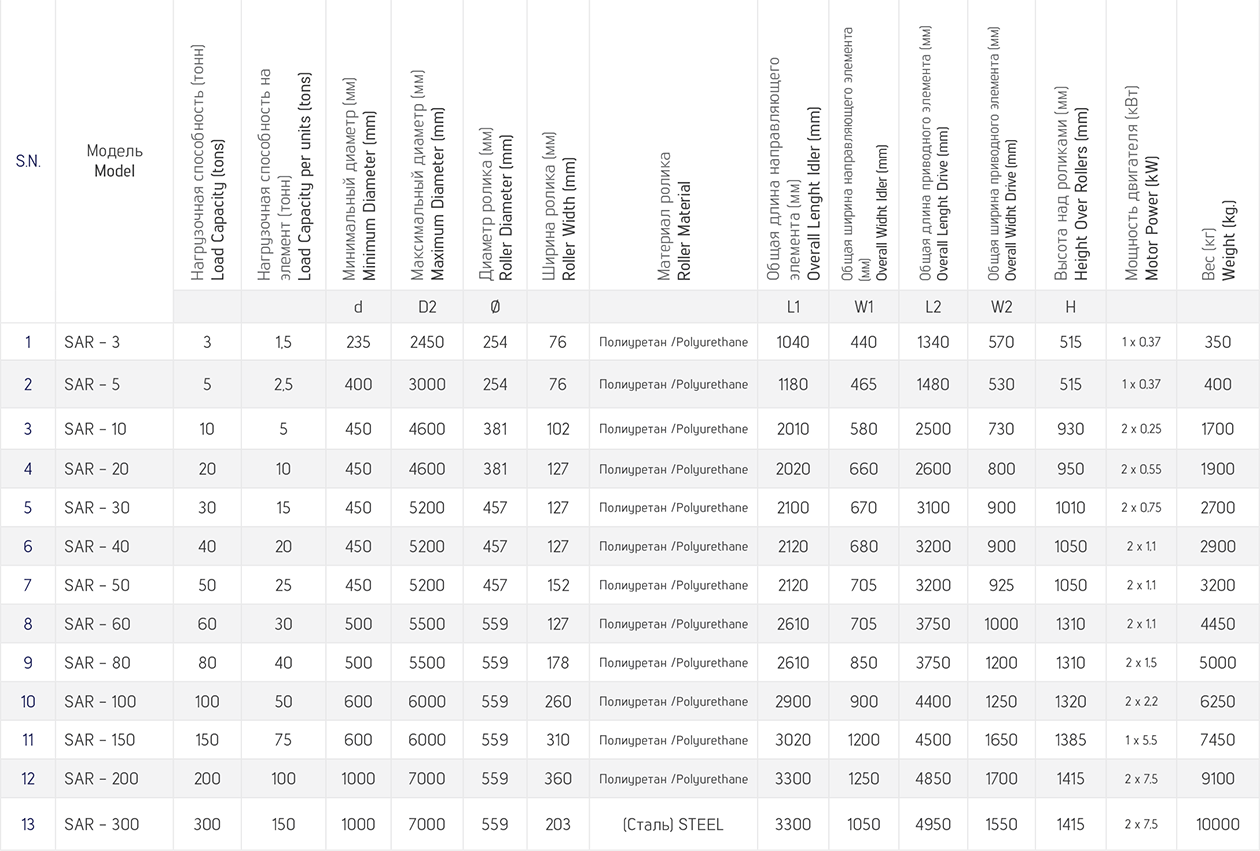

Bendmak Makine includes 3 to 300 tons self aligning rotators in its standard lists. However, custom production can be realized up to 600 tons.

B-SAR Application Areas

Silos

Wind Towers

Pressure Vessels

|

We will call you as soon as possible